ANU SPEC-E Lab

SPEctroscopy, Characterisation and Experimental Laboratory

Contact

Content navigation

About

Image

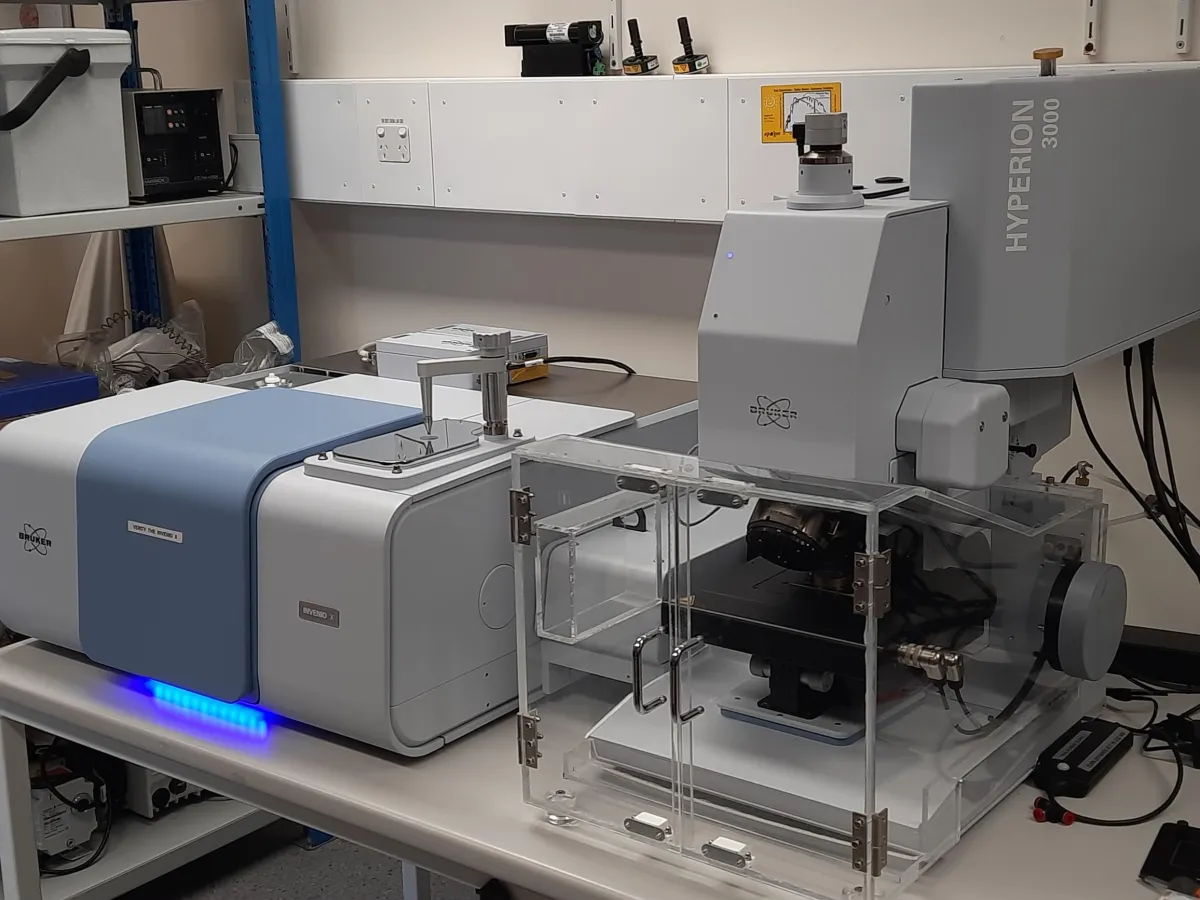

New Hyperion II and Invenio X FTIR

Instrument bookings & training can be arranged by contacting the Senior Laboratory Technician (see "Contacts" on the right). Instrument availabilities are listed in the calendar below.

Calendar

Current projects include:

- In situ analyses to characterize reactions as a function of temperature and gas atmosphere

- Detecting rock art coatings appropriate for dating

- Spatially mapping water diffusion in crystals and glasses

- In situ temperature-dependent reaction rates

- Investigating relationships between silicate glass structure, composition, thermal effects and spectra

More information

Location

Research School of Earth Sciences

Florey Building, Building 54

Mills Road

ACTON ACT 2601

-35.282906338024, 149.11375149166